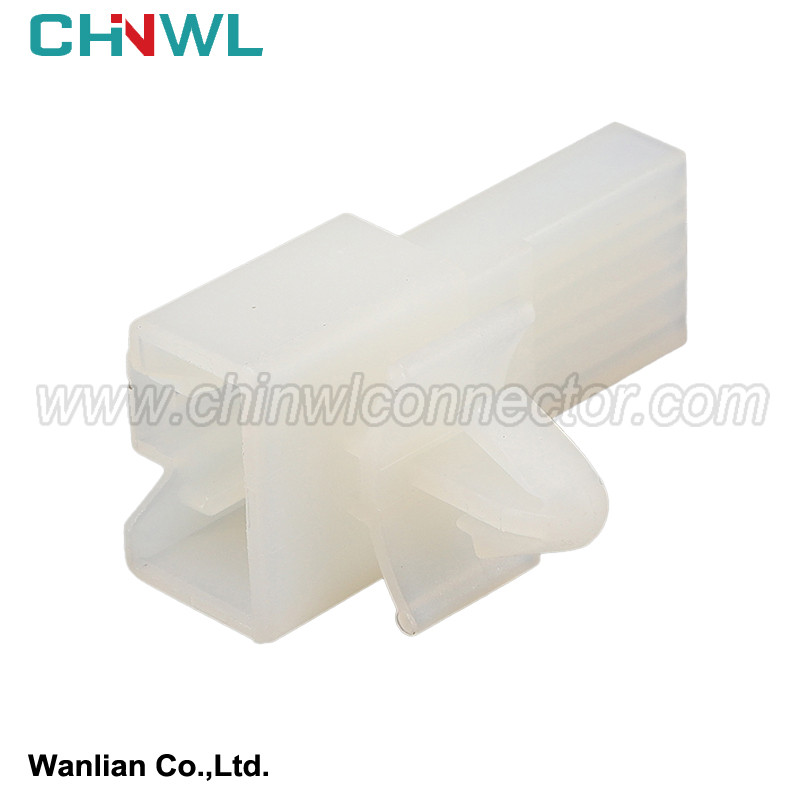

Wanlian #:

Mfr. #: DJY7039-0.6-21

|

Wanlian part number: |

|

|

|

Original number: |

|

DJZ7023-2.3-11 |

|

Gender: |

|

Male |

|

Specification: |

|

Housing: PBT+G; PA66+GF; PA66; PBT; Nylon |

|

Type: |

|

Connector |

|

TUV, TS16949, ISO14001, ISO 9001, RoHS conform: |

|

Yes |

|

MOQ: |

|

No minimum order quantity |

|

Supply sample: |

|

Yes |

|

Customized drawing with Decal, Frosted, Print are available as request |

|

Yes |

|

Payment method: |

|

We accept Paypal, TT, Alipay, West Union etc. |

|

Transportation method: |

|

Air Transport: UPS, DHL, FEDEX etc; Sea Transport; Railway Transport; Freight Forwarding etc. |

|

Production Capacity: |

|

1000000pieces/Month |

From the above introduction, it can be seen that the overall layout of the driver -driven machine needs to increase the all -in -one machine and controller in the overall layout of the automobile. These devices are external pendants. There is no need to make great changes to the engine and transmission mechanism. Therefore, it has been applied to some cars and bus at home and abroad, such as BMW enhanced BAS systems, GM Junwei BAS system. China's Pentium B70 car and Great Wall SUV also chose the BAS system. Shows a schematic diagram of the plug -in driving all -in -one machine.

At present, with the increase of the BISG motor power, its function has also changed. The electric motor of the BISG system of a mild hybrid vehicle has the characteristics of strong power when starting. Reduce the emissions of harmful substances. The structure of the transmission all -in -one is relatively simple, and only the motor and battery need to be added to the car. However, the control system of this system is relatively complicated, and it is necessary to control the motor to achieve the conversion of electric and power generation. The power of the AC generator can increase the torque of the automotive power system through the electrical drive system, assist the car to drive, and save 10%to 12%of the fuel.

(5) Character -like coupling characteristics.

In summary, the characteristics of the light hybrid power system using belt transmission are: relative to the gear, the belt transmission structure is simple, the material is light, the transmission is no noise, and the maintenance is convenient. Advantages are more suitable for economic models used in cities. Also due to the convenient installation of the all -in -one machine, some large hybrid buses also use a transmission structure.

For BISG, there are also some shortcomings.

① High requirements for the performance of the transmission belt. Due to the sliding and motion stagnation during transmission, some power losses will be caused, increasing the heat and wear of the belt, which will affect the life of the belt; the tension device of the belt needs to be specially designed to provide stable damping to eliminate the vibration of the belt.

② Because the belt is at the front of the engine, some inertia force has been offset when the automotive deceleration is braking, and its energy recovery effect must be weakened. In order to reduce the consumption of automotive inertia, the general engine uses the engine to break the oil and fire techniques when the car decelerates or taxi, so that the inertial energy is fully transmitted to the ISG motor through the crankshaft and belt, and the inertial energy recycling function is achieved.

(6) Type -tight wheel structure.

Figure 2.28 shows the tight structure of the BMW Active Hybrid 5 hybrid vehicle starting generator. In order to overcome the direction of the motor driver and the engine drive, the jitter of the loose edge of the transmission belt causes the band of the band, and the two -way reversing spring pre -pressure design is adopted. When the motor rotates the crankshaft clockwise, the upper belt is tightly tension, and the lower belt is relaxed, the tension wheel on the lower side will press the polycatulous belt in the influence of the spring to eliminate the slippery and vibration, Shows that when the engine -driven all -in -one is generated, the upper tensor is tightened to the upper side polyfront belt.

Simple instructions:

We have product Catalogue,please contact us on skype,WhatsApp or Email.

If you can't find a product on our website or catalog, We deal with over 10,000 items, our catalog doesn’t cover all products. And we are developing 100+ molds yearly, which means around 10 new products are created in our factory. So don’t go away, just send us your photo or part no, we’ll check for you.